There's Lightweight in Our Future

Lightweight construction is one of the major issues in the automotive industry, to meet the demands of fuel consumption reduction and consequently carbon emissions of cars. As the world market leader of roof systems, we are working on technologies to meet these challenges.

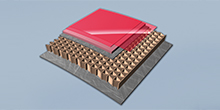

Polycarbonate: lightweight, impact-resistant, 3-D moldable

Polycarbonate is an alternative to glass. This material allows for achieving weight savings of around 50'% as compared to glass. Moreover, polycarbonate is extremely impact-resistant and has outstanding 3D molding properties.That is why we manufacture in Class A look fixed transparent moduls and panels made of polycarbonate. And the potential is far from being fully exploited: Fixed side windows, rear windows and casing parts that appear in glass optics are also conceivable. Additional functions such as heating filaments, solar cells or reflecting foils can also be integrated - we are already working on all of this.

Polycarbonate is an alternative to glass. This material allows for achieving weight savings of around 50'% as compared to glass. Moreover, polycarbonate is extremely impact-resistant and has outstanding 3D molding properties.That is why we manufacture in Class A look fixed transparent moduls and panels made of polycarbonate. And the potential is far from being fully exploited: Fixed side windows, rear windows and casing parts that appear in glass optics are also conceivable. Additional functions such as heating filaments, solar cells or reflecting foils can also be integrated - we are already working on all of this.

Webasto Glas ProTec®: Lightweight safety made easy

Another lightweight alternative is our proprietary Webasto Glas ProTec®.This safety glazing, a glass-plastic composite, allows for weight savings of 10 to 15 percent over conventional laminated safety glass. A highly tear-resistant PET film (polyethyleneterephthalate) is applied to the inner surface of curved single-pane safety glass (ESG). If this glass does break, the film holds the fragments together, thus protecting vehicle occupants from injuries from flying glass splinters. Since the protective effect of the film allows for the use of very thin (< 3 millimeters) glass panes, the panes are lighter.

Another lightweight alternative is our proprietary Webasto Glas ProTec®.This safety glazing, a glass-plastic composite, allows for weight savings of 10 to 15 percent over conventional laminated safety glass. A highly tear-resistant PET film (polyethyleneterephthalate) is applied to the inner surface of curved single-pane safety glass (ESG). If this glass does break, the film holds the fragments together, thus protecting vehicle occupants from injuries from flying glass splinters. Since the protective effect of the film allows for the use of very thin (< 3 millimeters) glass panes, the panes are lighter.

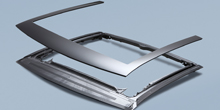

PU composites: Stable, lightweight, economical

Fiber-plastics composites, PU composites, are characterized by high stiffness at low weight, good 3D moldability as well as acoustic and heat-insulating properties. The weight savings over steel: 50 percent. That is why these are among our most important material components for the lightweight roof systems of the future. Because they are very stable these composite materials are ideal for body shell parts of up to 2 square meters in size. This is the lightweight construction material we use for the roof elements of an openable two-piece roof system whose parts can be completely removed and stowed in the trunk. The exterior surfaces are covered by a grained, thermoformed, weatherproof film, and the inside surfaces are flocked to match the vehicle's interior design. This roof system marks the first time a PU composite with a paper honeycomb core is being used on the outside of the vehicle.

Fiber-plastics composites, PU composites, are characterized by high stiffness at low weight, good 3D moldability as well as acoustic and heat-insulating properties. The weight savings over steel: 50 percent. That is why these are among our most important material components for the lightweight roof systems of the future. Because they are very stable these composite materials are ideal for body shell parts of up to 2 square meters in size. This is the lightweight construction material we use for the roof elements of an openable two-piece roof system whose parts can be completely removed and stowed in the trunk. The exterior surfaces are covered by a grained, thermoformed, weatherproof film, and the inside surfaces are flocked to match the vehicle's interior design. This roof system marks the first time a PU composite with a paper honeycomb core is being used on the outside of the vehicle.